With the rapid development of the degree of factory automation, high-precision assembly positioning, quality inspection, product identification, size measurement, etc., cannot be met by the human eye, and software and hardware products for machine vision have become standard in the manufacturing industry.

Machine vision acquires the image of the detected object through the camera, and these characteristic images are transmitted to the industrial computer at high speed. The characteristics are calculated by professional image analysis and processing software. According to the calculation results, the industrial computer can control the actuator to classify and eliminate , Alarm and other actions.

According to the production requirements for tablet computers on the industrial production line, combined with the process route of the tablet computer assembly process, according to the actual industrial field application, appropriate motion control hardware equipment was selected, and the motion control platform of the LCD registration and fitting system was reasonably designed . Based on the existing typical machine vision system, hardware such as industrial cameras, optical lenses, and frame grabbers suitable for the system are selected.The light source lighting system is uniquely designed, and a set of Alignment and lamination system based on machine vision for detecting positioning. Both the mechanism's motion control and image processing calculations use LabVIEW as a software development tool. The motion control module sets the user application layer, the drive control layer, the interface and the execution layer; the vision system module first calibrates the internal and external parameters of the camera used in the system based on the traditional camera calibration method, and then realizes the image in the software Compilation of acquisition module, improved RANSAC algorithm module, straight line fitting module and data calculation and communication module. This system verifies the stability and practicability of system functions and related algorithms through the application on actual production lines.

Industrial Tablet PC Manufacturer-Industrial Tablet PC-Industrial Touch Tablet PC

要求 Industrial panel pc system requirements in machine vision applications:

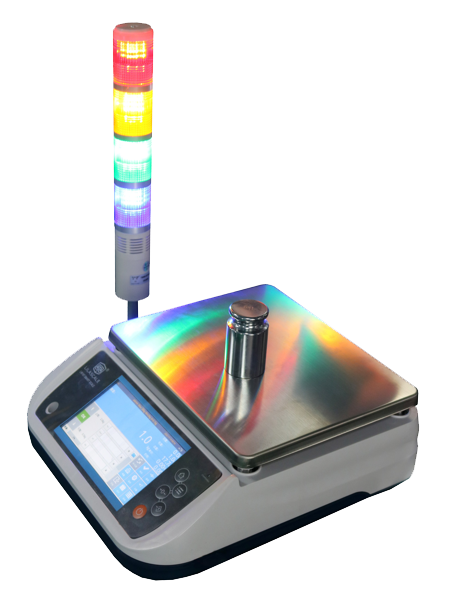

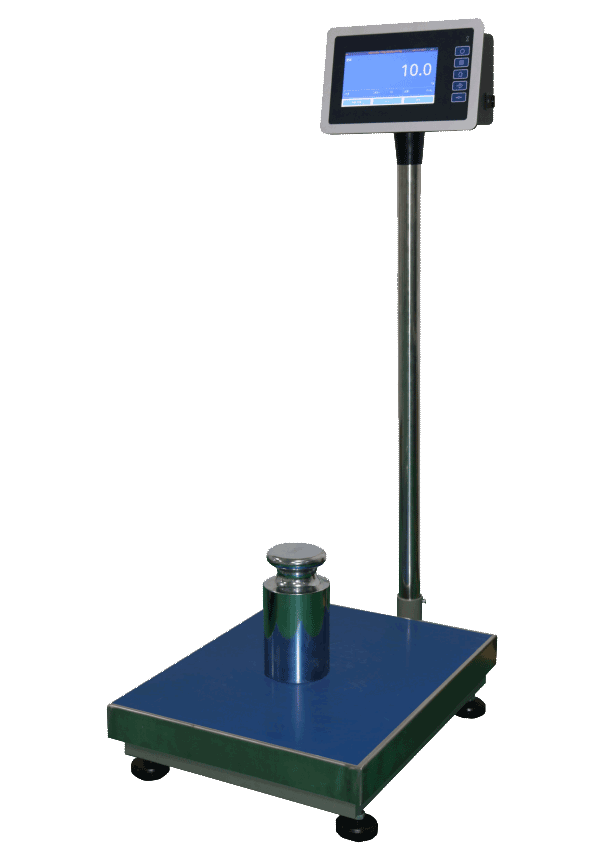

The entire machine system requires long-term work and has high requirements for the reliability of the main control equipment. The industrial computer of the main control equipment is installed in the terminal machine system. The terminal machine system is generally placed in the work workshop and has an automatic conveying system. The harsh environment such as vibration and dust has a greater impact; because there are not many data channels to be collected and the corresponding interfaces that need to be expanded are not many, generally 1-2 can be used; because the test results are to be printed, the interface needs to be printed; Debugging equipment, setting parameters, displaying results, etc., so the VGA interface and PS2 interface (separate) are necessary; because some PLC control equipment needs to be connected, the COM port is also necessary; if an abnormality is found during the test, an alarm must be promptly requested Therefore, the motherboard must have a buzzer, and the detection program generally uses this buzzer. The main control system must complete the functions of information collection, processing, analysis, transmission and communication. The CPU performance cannot be too low, but it is generally not required. High, applicable.

Industrial panel pc in machine vision application system description:

Equipment for detecting the quality of PCB surface graphics (such as surface defects, open circuits and short circuits) is used for the quality inspection of semi-finished products in the production process. It is a key technology for high-precision single-layer printed boards, especially multilayer printed boards. The test system integrates optics, precision machinery, recognition and diagnosis algorithms, and computer technology. During inspection, the machine automatically scans the PCB through a charge-coupled device (CCD) or laser, collects the image and sends it to an industrial computer for processing, and then compares it with standard data in the database to detect defects on the PCB. It is displayed or marked with a display or automatic identification system Defects for repairs. With the continuous development of science and technology, the traditional manual inspection and inspection can no longer meet the needs of production, and the birth of machine vision inspection is well in line with the development of modern production models. With its accuracy, repeatability, high speed, and objectivity The advantages such as low cost and so on have been promoted and applied in many fields, especially important achievements in detection technology. In the future, with the widespread popularity of industrial automation, machine vision inspection applications will also be further expanded.

Modern detection technology is the basis of industrial development. The accuracy and efficiency of measurement determine the level of development of manufacturing and even science and technology to a certain extent. Machine vision inspection is characterized by automation, objectivity, non-contact and high accuracy. Compared with image processing systems in the general sense, machine vision inspection systems emphasize precision, speed, and reliability in an industrial field environment.